- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

E-Commerce Conveyor Solutions from Dorner Conveyors

E-Commerce Conveyor Solutions

Dorner is a leading provider of efficient and reliable conveyor systems for the fast-paced e-commerce industry. With a deep understanding of the unique challenges and requirements of online order fulfillment, we’re committed to delivering conveyor solutions that ensure safe, accurate, and on-time processing of parcels and packages.

E-Commerce Industry Trends and Challenges

Rapid Growth and Rising Expectations

The Omnichannel Revolution

Managing High Order Volumes

The Race for Faster Shipping

Space Optimization Challenges

Adapting to Diverse Product Mixes

Labor Shortages and Automation

Dorner's Solutions for E-Commerce Challenges

Benefits of Dorner E-Commerce Conveyor Systems

✓ Fast and Accurate Order Fulfillment

- Conveyors designed for quick and efficient handling of packages and parcels of various sizes

- High-speed systems capable of processing thousands of orders per hour

- Precision engineering ensures accurate routing and sorting, minimizing errors

- Seamless integration with picking and packing stations for streamlined workflows

✓ Scalability and Flexibility

- Modular and customizable conveyor designs to accommodate growth and changing needs

- Easy reconfiguration to adapt to seasonal peaks or shifting product mixes

- Smooth integration with existing warehouse management and automation systems

- Future-proof your operations with expandable conveyor solutions

✓ Reliable Performance

- Robust construction and precision engineering for long-lasting, trouble-free operation

- Minimal downtime thanks to durable components and easy maintenance

- Consistent performance even under 24/7 operation in demanding environments

- Backed by Dorner’s industry-leading warranty and responsive support services

✓ Space Optimization

- Compact designs to maximize valuable warehouse floor space

- Vertical solutions like spiral and alpine conveyors for efficient use of cubic space

- Flexible layouts to navigate around obstacles and optimize existing infrastructure

✓ Enhanced Worker Productivity and Safety

- Ergonomic designs reduce physical strain on workers, improving efficiency and reducing fatigue

- Safety features such as emergency stops and guarding to protect employees

- Conveyors handle repetitive tasks, allowing workers to focus on value-added activities

✓ Improved Inventory Management

- Real-time tracking capabilities for enhanced visibility of products throughout the fulfillment process

- Efficient routing and sorting help maintain accurate inventory levels

- Seamless integration with inventory management systems for up-to-date stock information

✓ Cost-Effective Operations

- Reduced labor costs through automation of repetitive tasks

- Increased throughput leads to more efficient use of resources

- Energy-efficient designs help lower operational costs

- Long-term reliability minimizes maintenance expenses and extends system lifespan

By leveraging Dorner’s e-commerce conveyor solutions, businesses can achieve higher efficiency, improved accuracy, and greater scalability in their fulfillment operations. Our systems are designed to grow with your business, ensuring you stay competitive in the rapidly evolving world of online retail.

Key Applications in E-Commerce Operations

Receiving and Sorting

Efficient handling of incoming inventory is critical for e-commerce operations. Dorner’s conveyor systems streamline this process by:

- Facilitating quick unloading of delivery trucks and moving products to storage areas

- Integrating with barcode scanners and RFID systems for automated inventory tracking

- Utilizing high-speed sortation conveyors to accurately route products to appropriate storage locations

- Enabling efficient cross-docking for fast-moving items to reduce handling and storage time

Our conveyors ensure that new stock is processed quickly and accurately, setting the foundation for efficient order fulfillment.

Order Picking and Packing

The heart of e-commerce fulfillment lies in order picking and packing. Dorner’s solutions enhance this critical stage by:

- Providing ergonomic and space-saving conveyor layouts for streamlined order picking

- Offering accumulation and buffering conveyors for efficient order consolidation

- Integrating with pick-to-light and put-to-light systems for increased accuracy and speed

- Supporting zone picking strategies with intelligent routing capabilities

- Facilitating easy integration with automated picking systems and collaborative robots

Our conveyor systems help reduce walking time for pickers, minimize errors, and increase overall picking efficiency.

Shipping and Dispatch

Getting orders out the door quickly and accurately is crucial for customer satisfaction. Dorner’s conveyors support shipping and dispatch operations by:

- Providing reliable systems for fast and accurate order staging and loading

- Integrating seamlessly with shipping label applicators, scanners, and manifesting systems

- Offering incline and decline conveyors to efficiently move packages between levels

- Supporting high-speed sortation for routing orders to the correct carrier or shipping lane

- Facilitating easy integration with automated packaging systems

Our solutions help ensure that packed orders are swiftly and accurately processed for shipment, minimizing delays and errors.

Returns Processing

- Providing dedicated conveyors for efficient handling and sorting of returned products

- Integrating with inspection stations for quick quality checks and restocking decisions

- Offering accumulation zones for consolidating items for bulk processing

- Supporting seamless integration with inventory management systems for real-time stock updates

- Facilitating easy routing of items to appropriate departments (e.g., refurbishment, restocking, or disposal)

Our conveyors help streamline the returns process, allowing for quick processing and minimizing the impact on inventory management.

By addressing these key applications with tailored conveyor solutions, Dorner helps e-commerce businesses optimize their entire fulfillment process. From receiving to shipping and returns handling, our systems provide the efficiency, accuracy, and flexibility needed to meet the demands of modern online retail.

Dorner's E-Commerce Conveyor Solutions

2200 Series Conveyors

Dorner’s 2200 Series Conveyors are versatile belt and modular chain conveyors designed for light to medium-duty applications in e-commerce operations. These conveyors are ideal for product handling, transfers, and accumulation, offering reliable performance and easy maintenance. With a wide range of sizes, configurations, and accessory options, the 2200 Series can be tailored to your specific requirements.

2700 Series Conveyors

The 2700 Series excels in AGV/AMR (Automated Guided Vehicle/Autonomous Mobile Robot) applications, revolutionizing e-commerce warehouse automation. Its lightweight aluminum frame allows robots to carry heavier payloads without sacrificing mobility, effectively increasing overall system capacity. The low-profile design integrates seamlessly with various AGV/AMR models, maximizing vertical space utilization in warehouses.

3200 Series Conveyors

For demanding, high-throughput e-commerce applications, Dorner’s 3200 Series Conveyors deliver unmatched performance and durability. These heavy-duty belt and modular chain conveyors are built for long runs, 24/7 operation, and the constant demands of order fulfillment. With features like precision tracking, high-speed capabilities, and modular construction, the 3200 Series is the backbone of efficient e-commerce distribution.

DCMove Conveyors

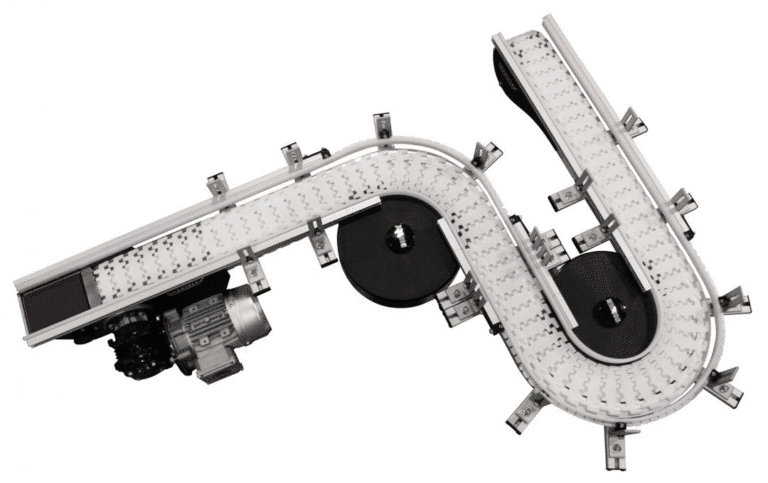

FlexMove Conveyors

Engineered Solutions

Our experienced engineers work closely with you to understand your specific challenges and requirements, developing custom conveyor systems that optimize performance, efficiency, and reliability.

From initial concept to final installation and support, Dorner’s Engineered Solutions Group ensures your e-commerce conveyor system is tailored to your exact needs.

Integration with E-Commerce Technologies

Seamless Integration with Popular E-Commerce Platforms

Dorner conveyors are engineered to integrate effortlessly with leading e-commerce platforms and warehouse management systems (WMS). This compatibility ensures:

- Real-time inventory updates as products move through the fulfillment process

- Automatic order routing based on SKU location and order priority

- Synchronized picking and packing operations for improved throughput

Real-Time Data Tracking and Analytics

Dorner’s conveyor systems support advanced data tracking capabilities, offering valuable insights into your e-commerce operations:

- Monitor conveyor performance and throughput in real-time

- Track individual order progress throughout the fulfillment process

- Analyze bottlenecks and optimize workflows based on data-driven insights

- Generate comprehensive reports on system efficiency and productivity

This level of data granularity enables businesses to make informed decisions, continuously improve processes, and respond quickly to changing demands.

Integration with Automation Technologies

Our conveyors are designed to work seamlessly with various automation technologies commonly used in e-commerce fulfillment:

- Robotic picking and packing systems

- Automated storage and retrieval systems (AS/RS)

- Vision systems for quality control and sortation

- RFID and barcode scanning technologies for accurate tracking

- Automated packaging and labeling systems

This integration capability allows for the creation of highly efficient, automated fulfillment centers that can significantly reduce processing times and labor costs.

Scalable and Future-Proof Solutions

Dorner’s approach to technology integration focuses on scalability and future-proofing:

- Modular designs allow for easy expansion and reconfiguration as your e-commerce business grows

- Open architecture supports integration with emerging technologies and future upgrades

- Customizable control systems can be tailored to your specific operational needs and existing IT infrastructure

By leveraging Dorner’s technology-integrated conveyor solutions, e-commerce businesses can create a more responsive, efficient, and data-driven fulfillment operation. This integration not only streamlines current processes but also positions your business to adapt quickly to future technological advancements in the e-commerce industry.

Streamlining E-Commerce Fulfillment with Dorner

Increased Throughput and Accuracy

- Our conveyors can achieve speeds up to 600 feet per minute, significantly accelerating product movement through your facility

- Seamless integration with automated picking systems for rapid order assembly

- Efficient sorting capabilities to handle diverse product ranges and order types

Precise product handling and tracking for improved order accuracy and reduced errors:

- Advanced tracking systems ensure each item is correctly routed throughout the fulfillment process

- Integration with barcode scanners and RFID technology for real-time inventory management

- Gentle handling features to minimize product damage during transport

Space Optimization and Efficiency

Compact and modular conveyor designs to make the most of available workspace:

- Low-profile conveyors that fit into tight spaces, maximizing vertical storage potential

- Flexible configurations, including incline and spiral conveyors, to optimize floor space utilization

- Modular designs allow for easy layout changes as your needs evolve

Efficient product flow and routing to minimize bottlenecks and improve productivity:

- Intelligent routing systems direct products along the most efficient path

- Accumulation zones prevent congestion during peak processing times

- Seamless integration with workstations for smooth order picking and packing operations

Scalability and Future-Proofing

Easily expandable and reconfigurable conveyor systems to accommodate business growth:

- Modular components allow for quick and cost-effective expansion as your business grows

- Adaptable designs support the integration of new technologies and automation solutions

- Scalable capacity to handle increasing order volumes without major system overhauls

Adaptable to changing product mix, order volumes, and fulfillment strategies:

- Versatile conveyor options to handle a wide range of product sizes and weights

- Customizable configurations to support various fulfillment models (e.g., batch picking, zone picking, or goods-to-person)

- Flexible control systems that can be easily reprogrammed to adapt to new operational requirements

With Dorner’s innovative conveyor solutions, e-commerce businesses can significantly enhance their fulfillment capabilities. Our systems are designed to grow with your business, ensuring you’re well-equipped to meet the evolving demands of the e-commerce landscape while maintaining efficiency and accuracy in your operations.

E-Commerce Conveyor Safety and Ergonomics

At Dorner, we understand that safety and ergonomics are paramount in e-commerce operations. Our conveyor systems are designed with these crucial factors in mind, ensuring a secure and comfortable working environment while maximizing productivity.

Worker Safety Features

Dorner’s e-commerce conveyor solutions incorporate numerous safety features to protect workers:

- Emergency stop buttons strategically placed for quick access

- Safety guards and enclosures to prevent accidental contact with moving parts

- Anti-pinch point designs to reduce the risk of injuries

- Lockout/tagout capabilities for safe maintenance procedures

These features not only comply with OSHA standards but often exceed them, demonstrating our commitment to creating the safest possible work environment.

Ergonomic Designs for Reduced Strain

Our conveyors are engineered to minimize physical strain on workers, reducing fatigue and the risk of repetitive stress injuries:

- Adjustable height options to accommodate workers of different statures

- Conveyor angles and speeds optimized for comfortable product handling

- Ergonomic workstations integrated with conveyor systems for efficient picking and packing

- Minimal reach requirements to reduce stretching and bending

- Smooth transitions between conveyor sections to prevent jarring movements

These ergonomic considerations help maintain worker comfort and efficiency throughout long shifts, particularly during high-volume periods.

Noise Reduction Technology

Recognizing the impact of noise on worker well-being and communication, Dorner incorporates noise reduction technologies:

- Low-noise belt materials and drive systems

- Vibration-dampening components to minimize operational noise

- Enclosed motor designs to reduce ambient noise levels

A quieter working environment contributes to reduced stress and improved concentration among workers.

Training and Best Practices

To complement our safety-focused designs, Dorner provides:

- Comprehensive training programs on safe conveyor operation and maintenance

- Documentation and guidelines for best practices in e-commerce conveyor usage

- Regular safety audits and recommendations for continuous improvement

Impact on Productivity and Employee Satisfaction

By prioritizing safety and ergonomics, Dorner’s conveyor solutions contribute to:

- Reduced workplace accidents and associated downtime

- Lower employee turnover rates due to improved job satisfaction

- Increased productivity through comfortable and efficient working conditions

- Enhanced ability to attract and retain skilled workers

Our focus on safety and ergonomics not only protects your workforce but also positively impacts your bottom line by creating a more efficient and satisfied team.

Comprehensive Services and Support

At Dorner, we’re committed to your success beyond the initial installation. Our comprehensive services ensure your e-commerce operations run smoothly and efficiently.

Expert Installation and Integration

- Skilled technicians provide seamless installation and commissioning

- Efficient setup minimizes disruption to existing operations

- Thorough testing and optimization ensure peak performance from day one

- Seamless integration with your existing systems and equipment

Comprehensive Training Programs

- Customized on-site and remote training for all staff levels

- Focus on safe operation, efficient workflows, and basic troubleshooting

- Hands-on instruction for operators and in-depth technical training for maintenance staff

- Emphasis on maximizing system uptime and throughput

Responsive Aftermarket Support

- 24/7 technical assistance for immediate help when you need it

- Quick access to spare parts to minimize potential downtime

- Preventive maintenance programs to keep your system running optimally

- Performance optimization services to adapt to your evolving needs

With Dorner, you gain more than a conveyor system – you get a long-term partner dedicated to the ongoing success of your e-commerce operations.

Why Choose Dorner for Your E-Commerce Conveyor Needs?

When it comes to optimizing your e-commerce operations, choosing the right conveyor partner is crucial. Here’s why Dorner stands out as the premier choice for your e-commerce conveyor needs:

Proven Expertise and Experience

- Over 50 years of experience in designing and delivering cutting-edge conveyor solutions

- Specialized focus on e-commerce applications, with a deep understanding of the industry’s unique challenges

- Track record of successful implementations across various e-commerce sectors, from small startups to major online retailers

- Continuous innovation to address evolving e-commerce trends and technologies

Customized Solutions for Every Application

- Tailored conveyor systems designed to fit your specific products, processes, and facility layout

- Collaborative approach that involves working closely with your team to identify pain points and goals

- Flexible designs that can adapt to your changing product mix and order volumes

- Scalable solutions that grow with your business, from initial setup to full-scale automation

Unmatched Quality and Reliability

- Precision engineering and robust construction ensure long-lasting performance

- Stringent quality control measures at every stage of manufacturing and installation

- Industry-leading warranty that reflects our confidence in our products

- Commitment to minimizing downtime and maximizing operational efficiency

Comprehensive Service and Support

- End-to-end support from initial consultation and design to installation and beyond

- Expert installation teams ensure seamless integration with your existing systems

- Comprehensive training programs for your staff to maximize system efficiency

- Responsive aftermarket support and maintenance services to keep your operations running smoothly

By choosing Dorner, you’re not just getting a conveyor system – you’re gaining a dedicated partner committed to your long-term success in the competitive e-commerce landscape. Our expertise, customized solutions, quality products, and comprehensive support ensure that your e-commerce operations will thrive, now and in the future.

Get Started with Dorner Today

Don’t let inefficient conveyor systems hold your e-commerce business back. Contact Dorner today to start your journey towards optimized, high-performance order fulfillment.

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy